ads go here

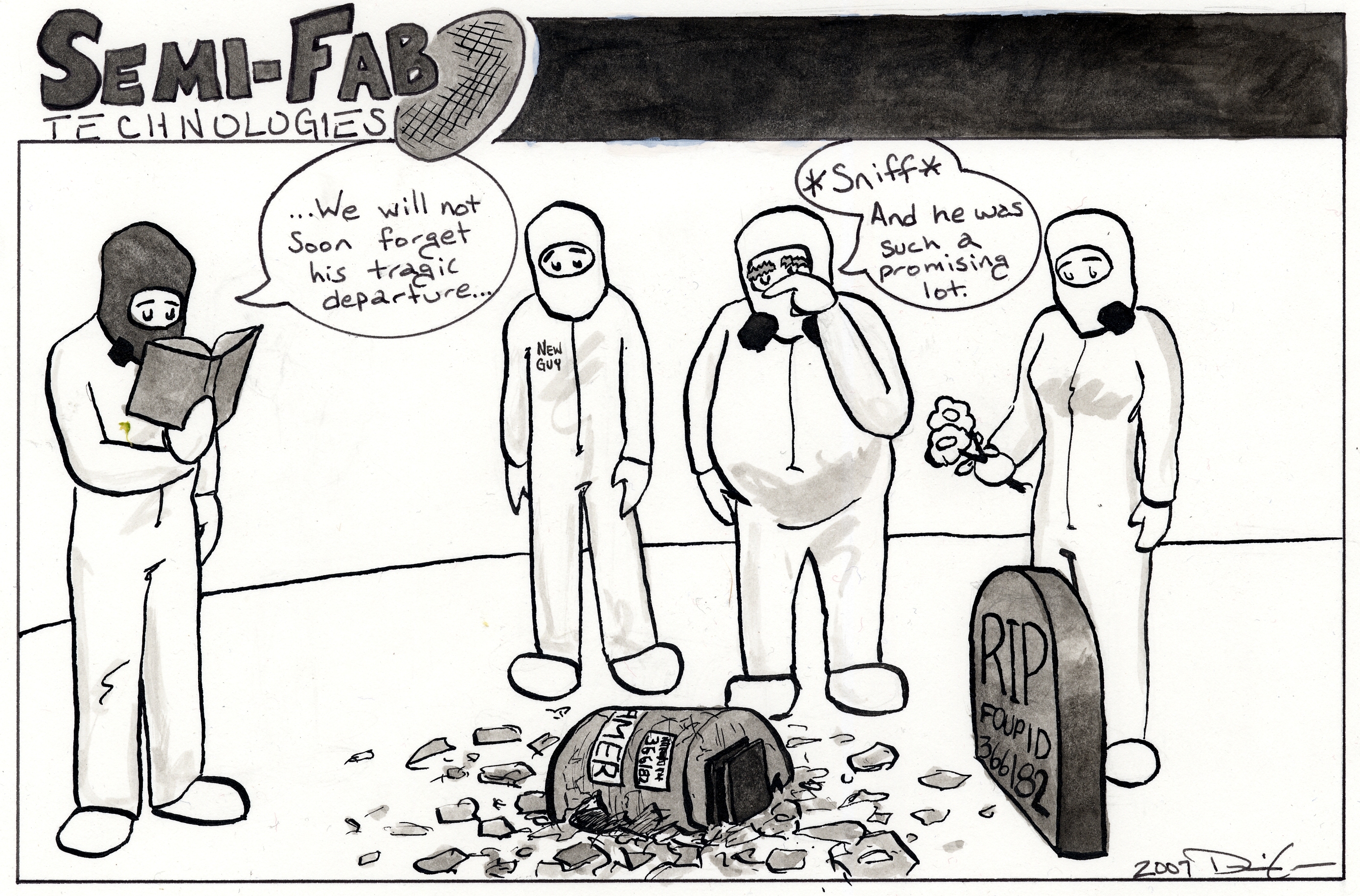

Recently Departed

Wafers are transported throughout the fab in FOUPs. Often, each FOUP contains wafers of the same batch, or more commonly called a lot. The FOUPs are sometimes carried by hand from station to station as the wafers journey through the manufacturing process. During the time I worked in the clean room, a lot on average would take 3-6 months from initial start to final production. To make this more rapid with less misplaced lots, the industry turned to automated conveyance of the FOUPs on ceiling mounted cars that carry the wafers to each station. Every once an a while, the car would halt in the middle of the track due to a faulty sensor or a FOUP not seating well in the clamps holding it 15 meters above the production floor. When this happens, the car technicians for their vendor representatives have to troubleshoot the car, often cycling the clamps in hope that reseating the FOUP regains positive contact on the problematic sensor. When these camps are cycled, locks are engaged under the FOUP to ensure the wafers aren't dropped like bombs from a B-17. Urban legend tell of a vendor struggling with a stubborn FOUP and car who once disengaged the clamps without engaging the locks. While his troubleshooting did not save the lot, his efforts proved that Newton's Laws still hold true in for clean rooms located on Earth. Funerals for lost lots were never so ceremonial. They typically consisted of lots of dirty looks, some heated arguments, paperwork, and lots of vacuum cleaners.

Comic Transcript

Vendor:

...We will not soon forget his tragic departure...

Fat tech:

*Sniff* And he was such a promising lot.