ads go here

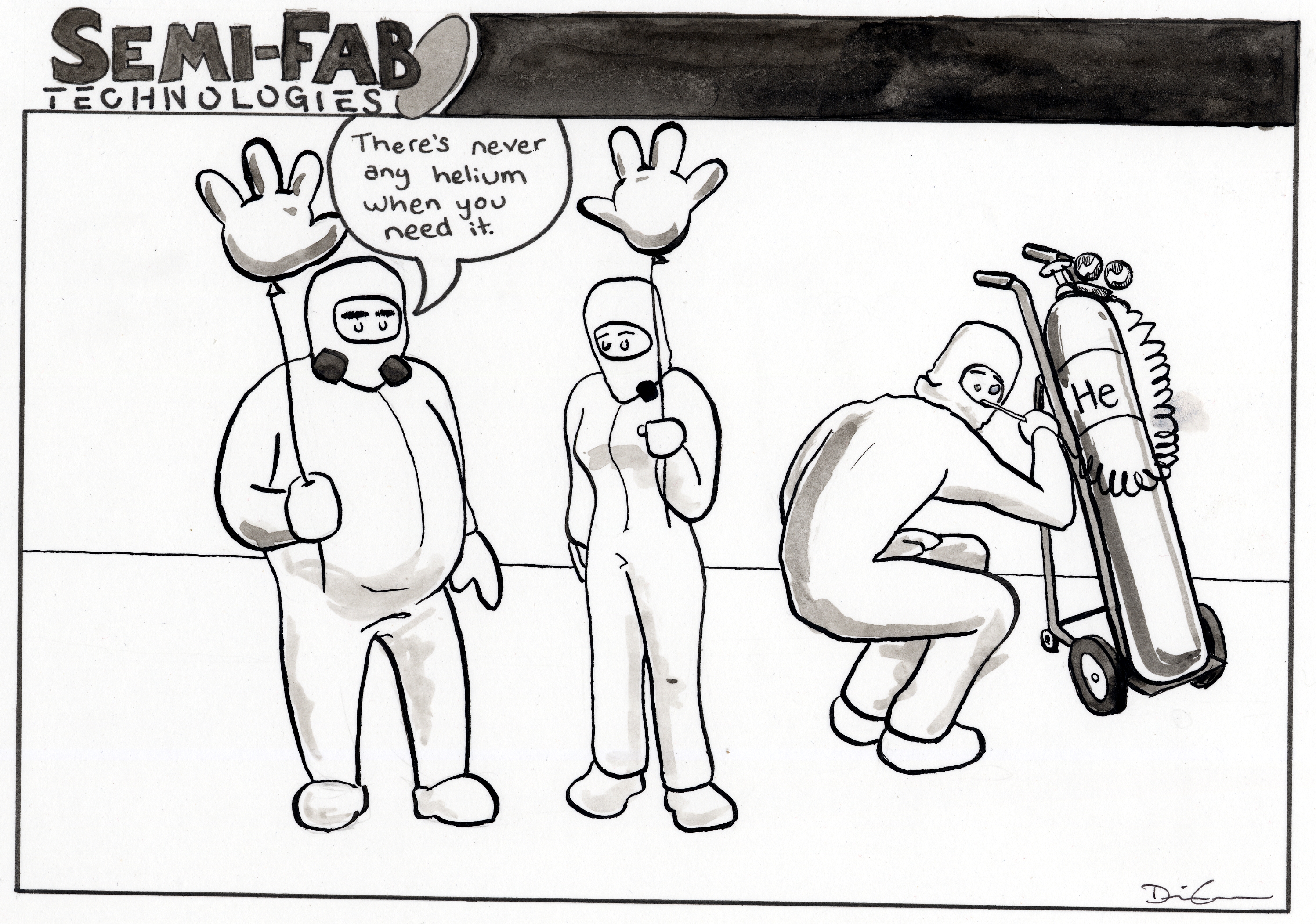

He2 Shortages

The LPCVD furnaces in a semiconductor fab must be able to pump the process chamber down to a near vacuum. Base pressures are often around 6 millitorr--which is fairly impressive for a 700C process environment holding ~150 wafers. Now, it not just wafers in an oversized hot, quartz mason jar, there are several injectors that introduces many different types of exotic gasses that leave miraculous properties on the surface of the waver, and sudden death in and around humans. Likewise, the atmosphere that we benefit from is product death if trace amounts of it make its way to the process chamber when wafers are being processed. So, after each maintenance event or repair, the whole gas delivery system and process chamber is leak checked to ensure everything is literally air tight. To facilitate this, a Helium detector is temporally attached to the pump side of the equipment and each fitting is checked by a burst of Helium gas to ensure none is able to seep into the system. Any leaks found must be addressed before the equipment can be put back into production. Thus, Helium bottles are necessary to get any down equipment back into production. Depending on the last time the gas supplier visited the facility, 1 to 3 bottles would be for maintenance to perform their tasks. On those days where there is only one bottle, you are often waiting for one tech to finish before you get your turn with the bottle, and thus, there is never enough Helium when you need it.

Comic Transcript

Fat Engineer:

There's never any Helium when you need it.